1. Production Process and Technical Features

Caprolactam-grade ammonium sulfate is a by-product of caprolactam (a precursor to nylon-6) production. Large crystals are formed through the following processes:

- Raw Materials and Reaction: High-purity liquid ammonia reacts with industrial sulfur to produce a sulfuric acid neutralization solution. Approximately 1.4 tons of ammonium sulfate is generated per ton of caprolactam.

-

Crystallization Technology:

- Deceleration Crystallization: Gradual reduction of stirring speed (e.g., from 750 rpm to 450 rpm) controls crystal growth rate, ensuring ordered formation and avoiding rapid nucleation of fine crystals.

- Additive Optimization: Manganese sulfate (1.0–1.1%) and ammonium sulfamate (0.70–0.75%) are added as compound additives to refine crystal structure and suppress impurity adsorption.

- Temperature and Pressure Control: Crystallization temperature is maintained at 60–62°C under a system pressure of 15–18 kPa, ensuring stable growth in a low supersaturation environment.

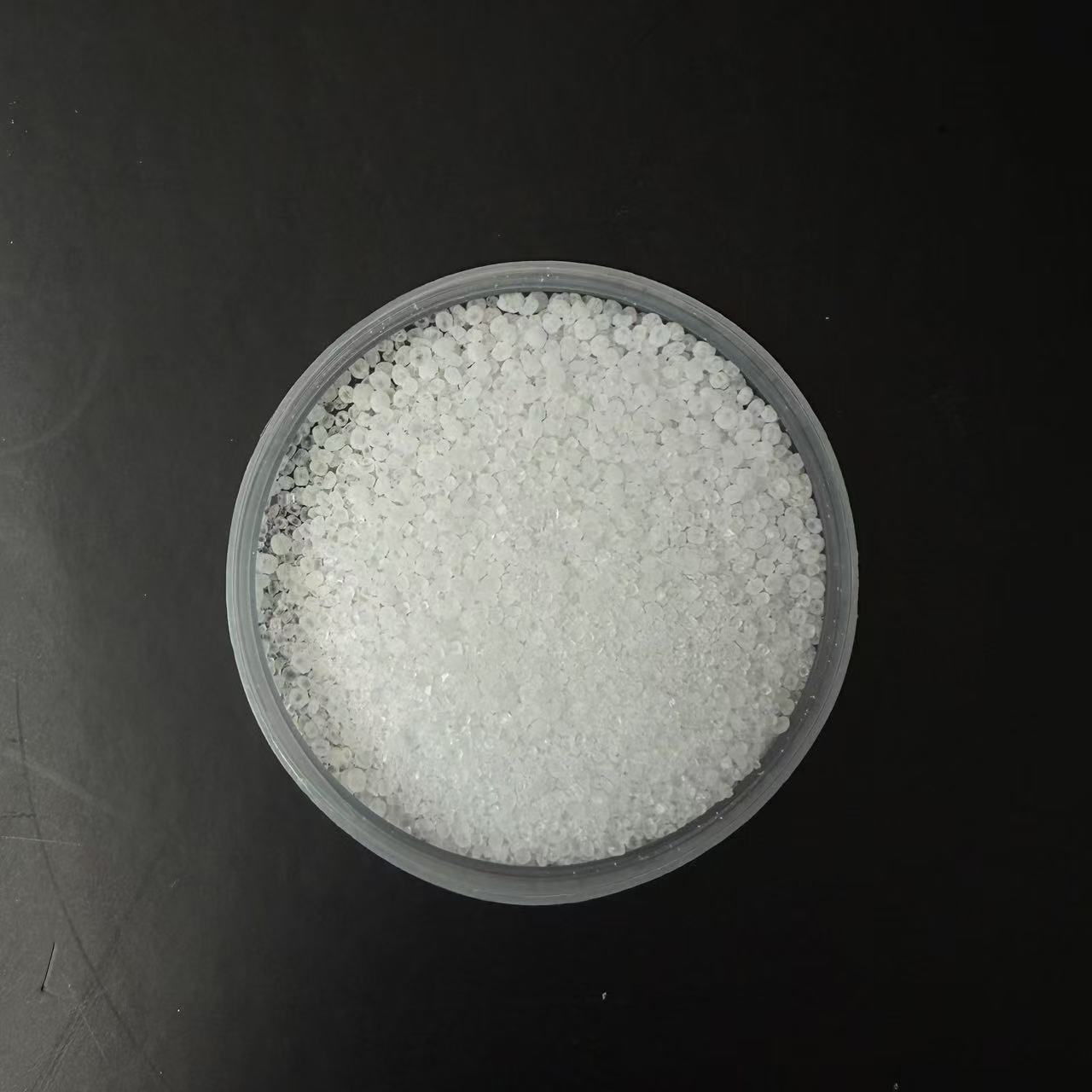

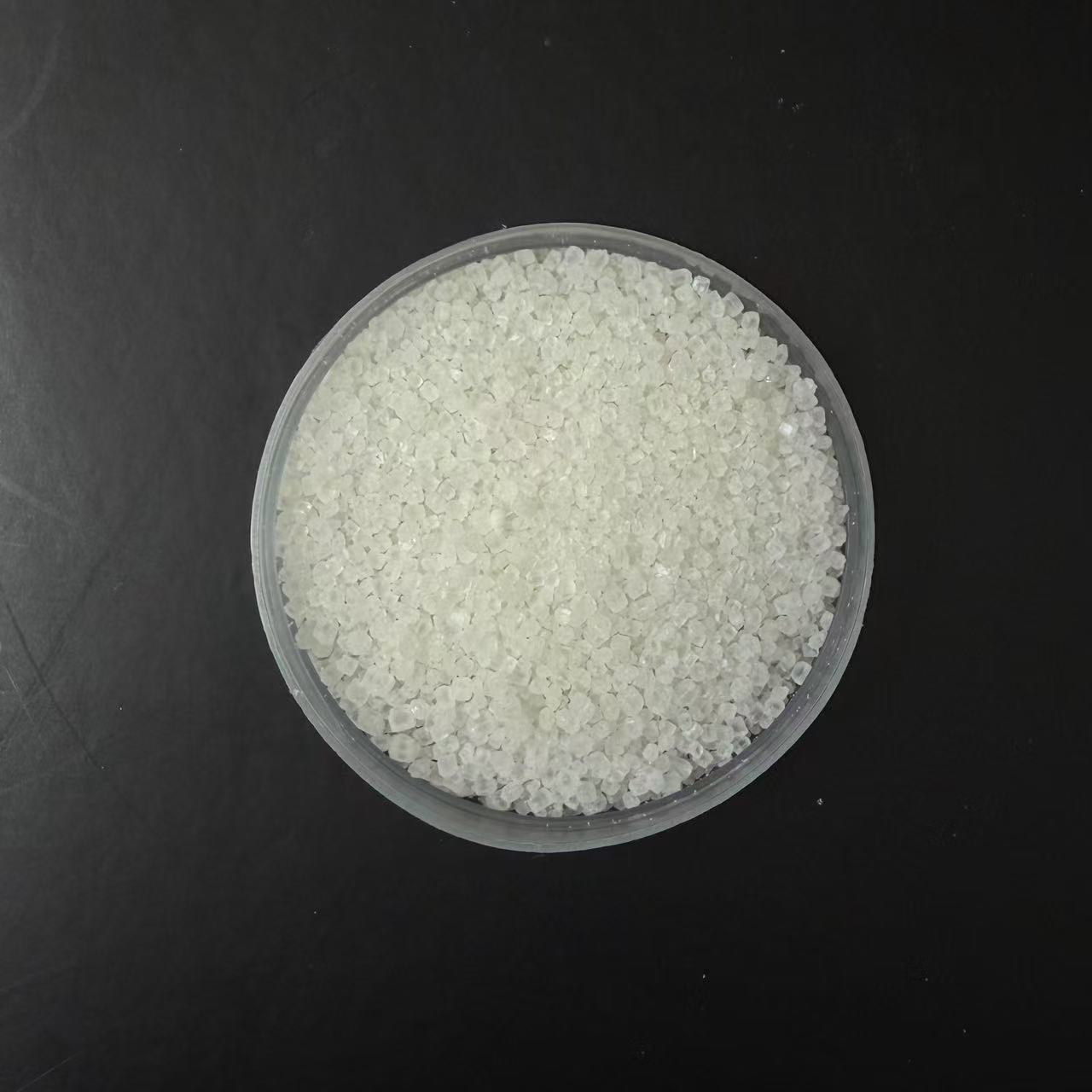

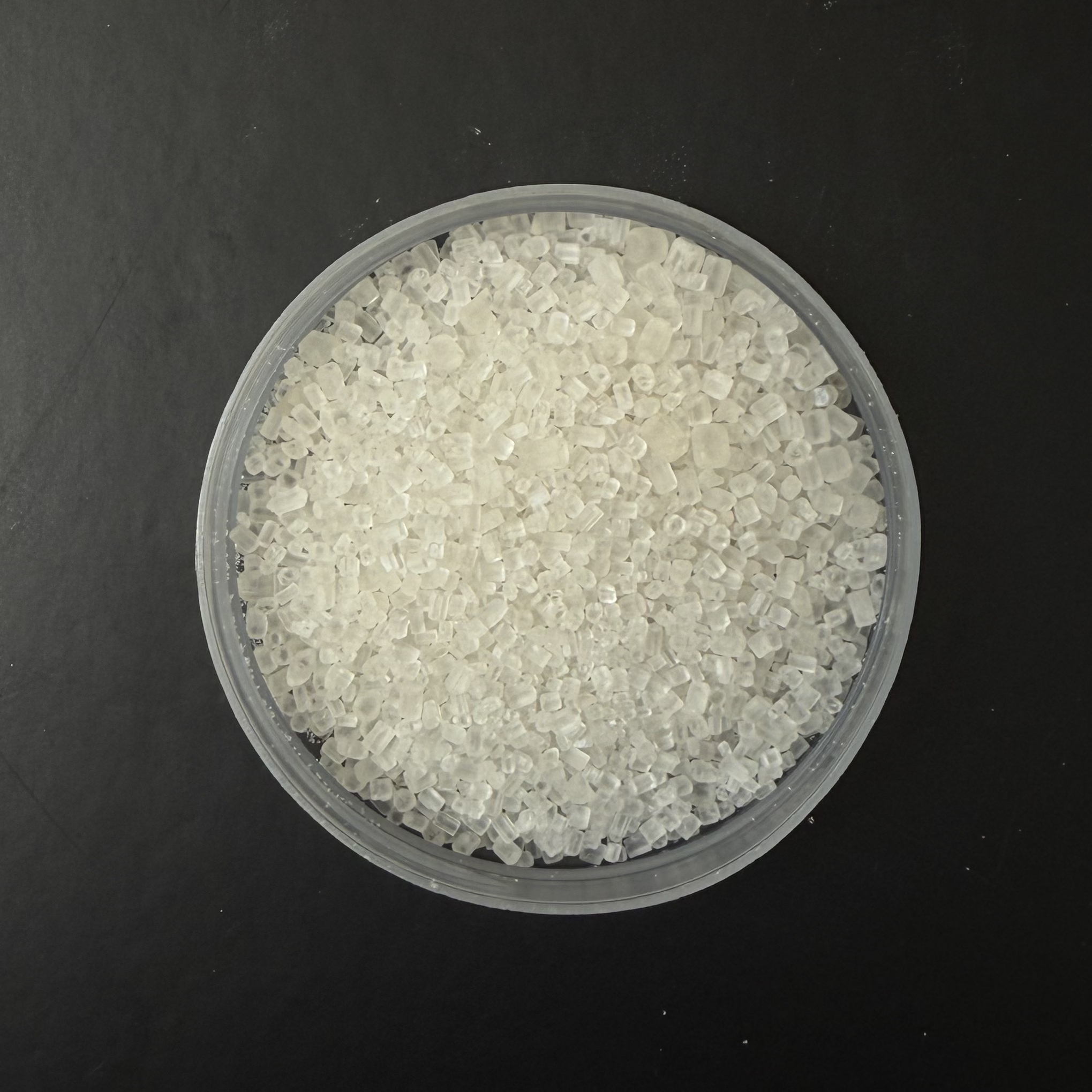

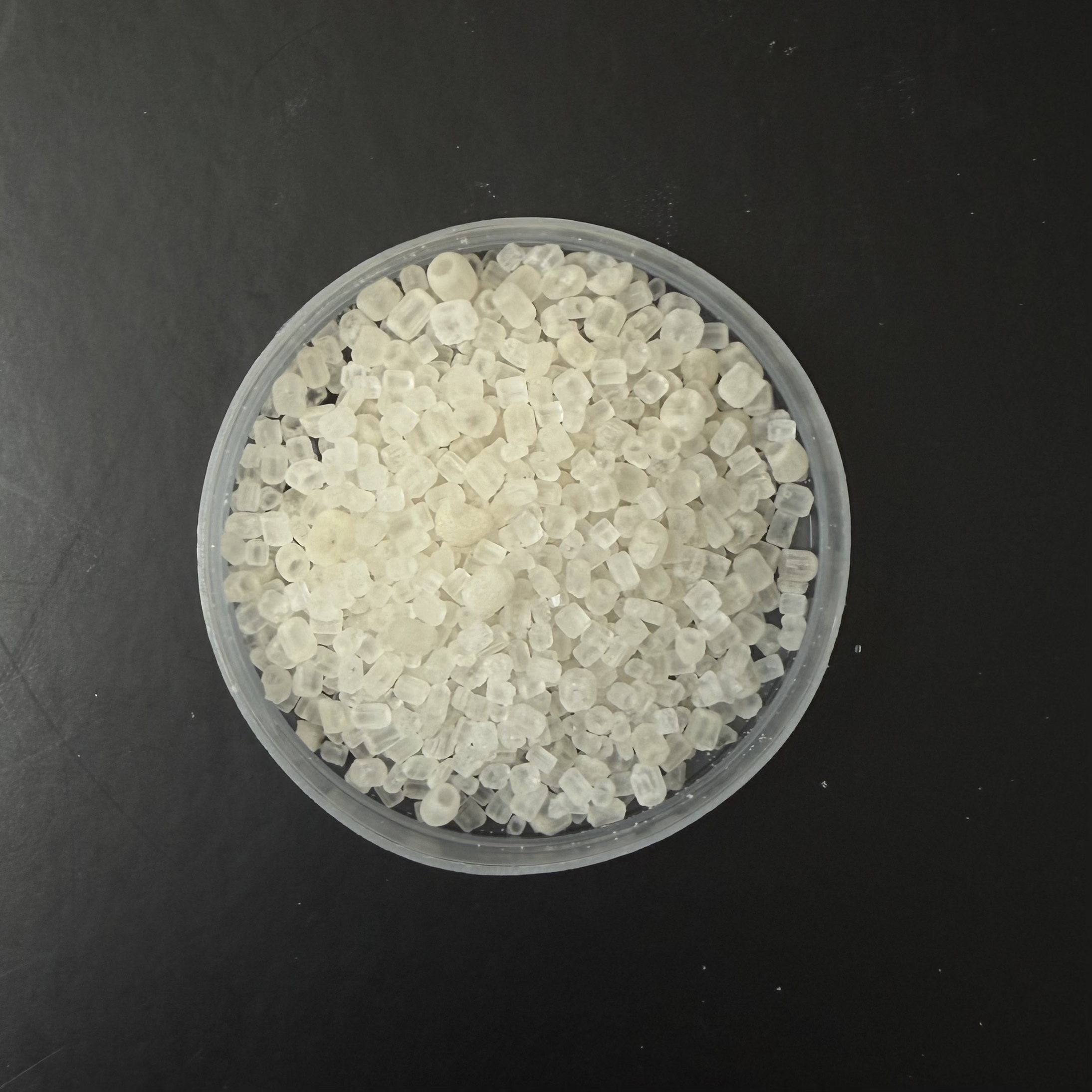

2. Technical Breakthroughs in Large Crystals

- Particle Size Advantage: Traditional processes yield crystals below 0.5 mm, while large-crystal technology achieves 1.4–4 mm, increasing product value (price premium of $30–45/ton).

- Energy Efficiency: Utilizes neutralization reaction heat for water evaporation, reducing reliance on external heat sources. Low-pressure steam is recycled for other processes.

- Reduced Losses: Two-stage separation (settling tanks and mother liquor tanks) minimizes caprolactam residue entrapment to <0.1%, enhancing purity.

3. Product Characteristics and Advantages

- Chemical Specifications: Nitrogen (N) ≥21%, sulfur (S) ≥24%, free acid ≤0.03%, moisture ≤0.2%, purity >99.5%.

- Physical Properties: Large crystals exhibit excellent flowability and anti-caking properties, ideal for bulk transportation and mechanized fertilization.

4. Applications

-

Industrial Uses:

- Pharmaceuticals and Biotechnology: Antibiotic fermentation, protein purification (salting-out agent).

- Rare Earth Smelting: Ion-exchange agent for rare earth ore processing (5 tons required per ton of ore).

-

Agricultural Uses:

- High-End Water-Soluble Fertilizers: Suitable for high-value crops (fruits, vegetables) and sulfur-deficient soil remediation (India, Brazil).

- Direct Fertilization: Slow nutrient release reduces field losses.

5. Market and Outlook

- Production Capacity: China dominates 70% of global production, targeting India, Southeast Asia, and Brazil.

- Demand Growth: Driven by lithium battery cathode materials, global demand is projected to triple by 2030 compared to 2024 levels.